| AIR & GAS DRYING

SYSTEM |

|

|

|

Products/Packaged

Systems |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

To proceed for the selection of Air & Gas Dryer, it is recommended

to go through the contents very carefully as explained in the

COMPRESSED AIR SYSTEM.

Air dyer is one of the

most critical and important equipment of an ideal compressed air

system. Most of the times industry selects a dryer according to

the standard model of a dryer of any particular brand without

knowing their actual dryness ( Dew point) required for the

application. As a result of this, sometimes over designed dyer

will unnecessarily cost more in terms of its capital cost,

operation and maintenance cost and sometimes less designed dryer

will lead to frequent application, process and instruments

failure,

Considering the above

Calorie HNT specializes in following type of air dryers.

|

|

Refrigeration Type |

|

|

Regenerative Adsorption Type |

|

|

Membrane Type |

|

|

|

|

Regenerative Adsorption Type is further classified as |

|

|

Heatless Type |

|

|

Internally Heated Type |

|

|

Externally Heated Type |

|

|

No loss Split Flow Type |

|

|

Heat of

Compression Type |

|

|

|

|

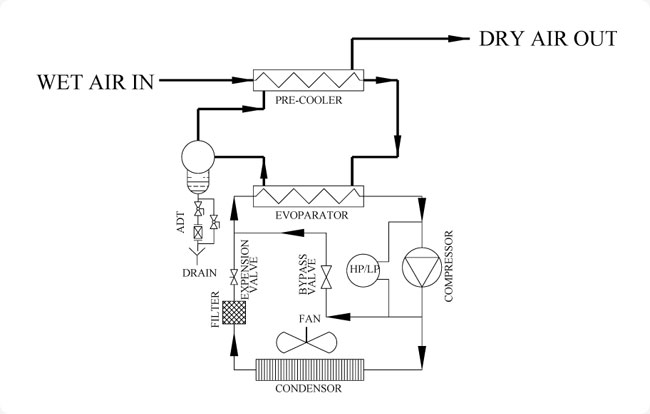

REFRIGERATION TYPE |

|

|

Principle

The temperature of the compressed air is brought down to 2-3Β° C in

an heat exchanger through a refrigeration cycle. As a result of

cooling moisture present in the compressed air gets condensed and

knocked out in a moisture separator. Dry air having a pressure dew

point (+) 3Β° C is available for use. |

|

|

|

|

|

|

Process

The process is

continuous and non cyclic. The saturated compressed air enters

into a heat exchanger where it is partially cooled by the chilled

air coming out from the moisture separator. This partially cooled

air is further cooled down to (+) 3Β°C in the evaporator of the

refrigeration cycle. A complete refrigeration systems which

consists of a compressor, condenser, expansion valve and

evaporator ensures the continuous cooling of the incoming

compressed air. The systems is automatic with all relevant safety

interlocks and proper instrumentation. The moisture of the

outgoing compressed air is knocked down in a moisture separator

and drained out through and automatic drain valve. The process is

continuous and non cyclic. The saturated compressed air enters

into a heat exchanger where it is partially cooled by the chilled

air coming out from the moisture separator. This partially cooled

air is further cooled down to (+) 3Β°C in the evaporator of the

refrigeration cycle. A complete refrigeration systems which

consists of a compressor, condenser, expansion valve and

evaporator ensures the continuous cooling of the incoming

compressed air. The systems is automatic with all relevant safety

interlocks and proper instrumentation. The moisture of the

outgoing compressed air is knocked down in a moisture separator

and drained out through and automatic drain valve. |

|

|

Specifications |

|

| Capacity |

- |

100 to 15,000 Nm3/hr |

| Pressure |

- |

5 to 16 Bar (g) standard . ( Higher Pressure

on demand) |

|

Pr. Dew Point |

- |

(+) 3ΒΊ C |

|

|

|

It is very important for proper selection of air dryer. Selection

depends upon many factors like capacity, pressure, Temperature,

dew point, location, type of air compressor and mainly the

application. A improper selection may cost in terms of capital

investment and operational cost. Hence it is recommended to

specify the complete details to Calarie HNT and let them suggest a

right kind of dryer. |

| |

|

REGENERATIVE ADSORPTION TYPE |

|

|

Principle

The adsorption type dryers are also termed as desiccant dryers.

Theses type of dryers are usually used where low dew point in the

range (-) 40Β°C ~ (-) 80Β°C is required. A desiccant is used for the

adsorption of moisture. It is twin column and cyclic process. When

one column is in adsorption mode, the other is in regeneration

mode. The regeneration of desiccant is done by heating the

desiccant followed by subsequent cooling |

|

| |

|

HEATLESS TYPE |

|

|

The principle is the same as explained above but in this case the

desiccant is regenerated by small quantity of dry air itself.

There is no heating is required, hence it is termed as Heatless.

The dry air required for the regeneration is basically a loss of

dry compressed air which is in tune of 7-12% for a consistent dew

point of (-) 40Β°C. This loss is termed as purge loss. Since there

is loss of dry air , it is only recommended for a smaller

capacities |

|

|

Specifications |

|

| Capacity |

- |

5 to 1000 Nm3/hr |

| Pressure |

- |

5 to 16 Bar (g) standard . (

Higher Pressure on demand) |

|

Pr. Dew Point |

- |

(-) 40ΒΊ C |

|

|

|

|

INTERNALLY HEATED TYPE |

|

|

This type of dryer has electrical heater embedded inside the

desiccant columns. These dryers are most suitable for the

application where very low dew point in the range of (-) 60 ~ (-)

80Β°C is required. Regeneration of the desiccant is done by heating

of the desiccant and purging with the small quantity of the dry

air. |

|

|

Specifications |

|

| Capacity |

- |

50 to 8,000 Nm3/hr |

| Pressure |

- |

5 to 16 Bar (g) standard . (

Higher Pressure on demand) |

|

Pr. Dew Point |

- |

(-) 40ΒΊ C to (-) 80 ΒΊ C |

|

|

|

|

EXTERNALLY HEATED TYPE |

|

|

This type of dryer has electrical heater installed outside the

desiccant columns. These dryers are most suitable for larger

capacities beyond 500 Nm3/hr and for the application where dew

point i(-) 40Β°C is enough. Regeneration of the desiccant is done

by heating of the desiccant and purging with the atmospheric air

from an external air blower. There is NO LOSS of compressed air. |

|

|

Specifications |

|

| Capacity |

- |

500 to 15,000 Nm3/hr |

| Pressure |

- |

5 to 16 Bar (g) standard . (

Higher Pressure on demand) |

|

Pr. Dew Point |

- |

(-) 40ΒΊ C |

|

|

|

|

NO LOSS SPLIT FLOW TYPE |

|

|

This type of dryer similar to externally heated type but there is

no external blower is required. The main stream of the compressed

air is divided into two streams. The main stream enters one of the

drying column and gets dried while a small portion of second

stream is routed trough an external heater and enters into the

second column for regeneration and after regeneration it combines

with the main stream. The regeration is done in a closed loop. In

this dryer one regeneration cooler and one after cooler is used.

These dryers are most ideal for larger capacities beyond 500

Nm3/hr and for the application where dew point i(-) 40Β°C is

enough. |

|

|

Specifications |

|

| Capacity |

- |

500 to 15,000 Nm3/hr |

| Pressure |

- |

5 to 16 Bar (g) standard . (

Higher Pressure on demand) |

|

Pr. Dew Point |

- |

(-) 40ΒΊ C |

|

|

|

|

HEAT OF COMPRESSION TYPE |

|

This type of dryer has virtually negligible operational cost as

compared to other dryers. It is again a no loss type and no heater

is required for regeneration. In fact the hot air coming out from

the compressor itself is sufficient for the regeneration. But the

minimum temperature should be 120Β°C. This temperature is not

possible for smaller capacity compressor , hence HOC type dryer is

for larger capacity. This dryer is always installed near the

compressor so as to use maximum heat. In this dryer, first of all

the hot air from the compressor enters into one column and picks

up the moisture of the desiccant and knocks down its moisture

after getting it cooled in a cooler and then it enters into the

second column for drying. The cycle repeats after pre set

intervals. These dryers are most ideal for larger capacities

beyond 500 Nm3/hr and for the application where dew point i(-)

40Β°C is enough. This type of dryer has virtually negligible operational cost as

compared to other dryers. It is again a no loss type and no heater

is required for regeneration. In fact the hot air coming out from

the compressor itself is sufficient for the regeneration. But the

minimum temperature should be 120Β°C. This temperature is not

possible for smaller capacity compressor , hence HOC type dryer is

for larger capacity. This dryer is always installed near the

compressor so as to use maximum heat. In this dryer, first of all

the hot air from the compressor enters into one column and picks

up the moisture of the desiccant and knocks down its moisture

after getting it cooled in a cooler and then it enters into the

second column for drying. The cycle repeats after pre set

intervals. These dryers are most ideal for larger capacities

beyond 500 Nm3/hr and for the application where dew point i(-)

40Β°C is enough. |

|

|

Specifications |

|

| Capacity |

- |

500 to 15,000 Nm3/hr |

| Pressure |

- |

5 to 16 Bar (g) standard . (

Higher Pressure on demand) |

|

Pr. Dew Point |

- |

(-) 40ΒΊ C |

|

|

|

|

EXTREMELY HIGH OR LOW PRESSURE DRYER |

|

Under this category Calorie HNT has a specific design and the

systems are made as per the individual customers requirement. The

specification under this category Under this category Calorie HNT has a specific design and the

systems are made as per the individual customers requirement. The

specification under this category |

|

Specifications |

|

| Capacity |

- |

50 to 10,000 Nm3/hr |

| Pressure |

- |

0.5 to 300 Bar (g) |

|

Pr. Dew Point |

- |

(-) 20ΒΊ C to (-) 80 ΒΊ C |

|

|

|

|

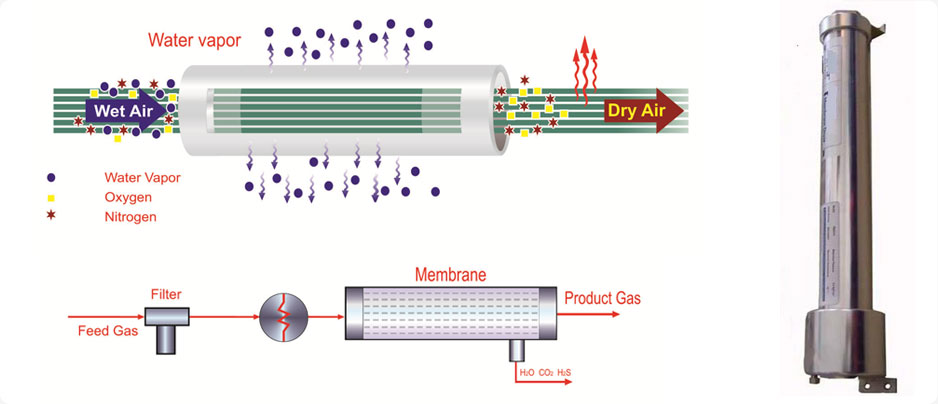

MEMBRANE TYPE |

|

|

A tube is filled with hollow membranes that allow compressed air

to pass but remove water vapor. These dryers give a -80Β°F dew

point relative to the incoming air temperature. Membrane dryers

have NO MOVING PARTS and require NO ELECTRICITY & MAINTENANCE, and

therefore have a very long life. It occupies 1/10th of the space

as compared to other dryers. There are many model of the membrane

module which depends upon its size and capacity. A combination of

many such modules enhance the capacity and dew point. |

|

|

|

|

|

Specifications |

|

| Capacity |

- |

5 to many million Nm3/hr |

| Pressure |

- |

5 to 14 Bar (g) standard |

|

Pr. Dew Point |

- |

(-) 20ΒΊ C to (-) 40ΒΊ C |

|

|

|