|

Products/Packaged

Systems |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

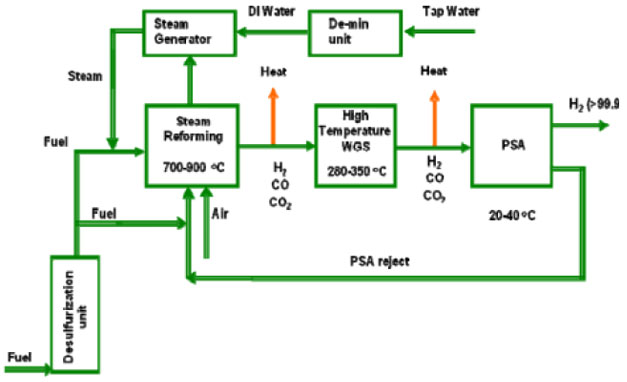

Principle

Hydrogen Generation

from hydrocarbon fuel is based on steam reforming of the fuel in a

catalytic reactor. The reactor facilates the conversion of the

hydrocarbon into hydrogen enriched gas in presence of steam. The

reaction popularly know as steam reforming reaction.

Process

The feed fuel is

first purified from contaminants like sulfur based compounds and

fed to the reformer reactor which is filled with catalyst. Steam

reforming reaction takes place at 700 ~ 900ΒΊ C. As a result of

this reaction primarily H2, CO & CO2 is formed. The CO from this

stream is removed by the water gas shift reaction. The resulting

H2 enriched gas is further cooled to remove water. This gas stream

now enters into a PSA Unit where it is further purified to level

better than 99.999%..

Design Features

The plant is designed for maximum heat recovery in order to

minimize the need of additional fuel consumption. It is properly

instrumented and automatically controlled by industrial grade PLC

system. Color touch screen display HMI ( Human Machine Interface)

shows all the parameters and alarms. The control system is

realized following a "fail safe" technology in order to maximize

plant safety. Plant design and construction comply all relevant

international standards and E.C directives. |