|

Products/Packaged

Systems |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

» |

|

|

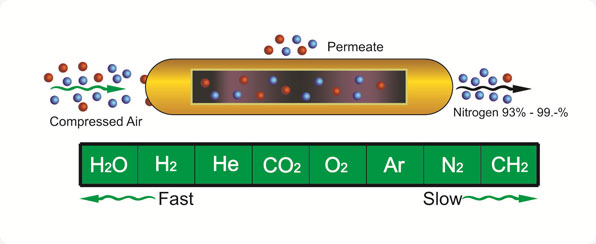

Principle

Membranes separate

gases by the principle of selective permeation across the

membranes wall. For nitrogen polymeric membranes, the rate of

permeation of each gas is determined by its solubility in the

nitrogen membrane material, and the rate of diffusion through the

molecular free volume in the nitrogen membrane wall. Gases that

exhibit high solubility in the nitrogen membranes, and gases that

are small in molecular size, permeate faster than larger, less

soluble gases.

Fast" gases permeate

through the nitrogen membrane wall more readily than "slow" gases,

thus separating the original gas mixture into two streams. The

purity of the desired streams can be adjusted by changing the

operating conditions.

|

|

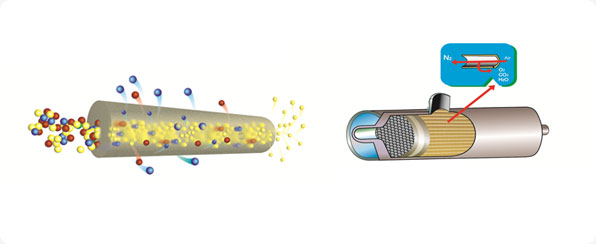

Process

Membrane

processes rely on the fact that under pressure, gases tend

to be permeated through the wall of the hollow fibre

membranes. Faster gases permeate faster than slower gases.

When a treated compressed air passed through the membrane,

water, carbon dioxide and oxygen permeates and vented to

atmosphere where as Nitrogen comes out in the main stream

as the product gas.. It is a continuous process. No

depressurization or regeneration is required |